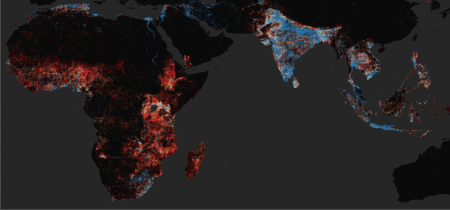

As the largest economy in Africa, with huge gas reserves and high solar energy potential, Nigeria has all the natural resources necessary to meet the growing demand for electricity. However, the inadequate energy infrastructure still leaves a significant part of the population without power or relying on oil-fired back-up generators. If Nigeria can improve its energy infrastructure and unlock its gas-to-power generation potential, it paves the way to integrating low-cost renewable energy, bringing electricity and development opportunities to rural villages, driving industrial growth and employment, and increasing prosperity across the country.

There is no doubt that gas has an important role to play in meeting Nigeria’s electricity demand, but to achieve this, there is an urgent need to reform the gas and electricity sectors. The poor condition of the gas transmission and distribution system is a major constraint as domestic supply shortages and insufficient pressure severely affect the reliability of the power supply. Poor planning has resulted in stranded generation assets and transmission bottlenecks. Inadequate maintenance of an aging and inefficient infrastructure means that peak generation is well below its full potential. Without structural reforms and integrated energy planning, the ability to meet the growing electricity demand is challenging.

However, advanced power system modeling, which helps to identify the lowest total cost energy solution while considering system constraints, shows that Nigeria is indeed in a position to achieve its ambitious targets by 2030. By developing a balanced thermal portfolio combining baseload gas and flexible gas power generation, the power system will be capable of integrating a high level of renewables and operating efficiently. But significant flexibility needs to be built into the power grid, to make it capable of responding to daily variations in demand and withstanding the intermittent nature of renewables.

Not all gas-fired power plants are the same

Even if from a pure cost perspective, reciprocating gas engine and combined cycle gas turbine technologies offer comparable results, gas engine technology adapts faster to balance the intermittency and unpredictability that characterize addition of renewables into the power generation mix and thus facilitate their growth and integration into the system. In addition to being robust and versatile to manage the current generation and transmission side disturbances in an efficient manner, there are three important advantages that ICE technology offers for the future; the first is flexibility, the ability to quickly adjust load in response to supply fluctuations from renewables; the second is modularity, gas engine plants can be sized to requirements, for a city, for manufacturing industries, or for local micro-grids; and the third is low water consumption, which is an important consideration in view of Nigeria’s long dry seasons.

To maintain a balanced system, flexible forms of electricity must be available to ramp up output at the same rate that wind or solar output fluctuates. Systems need to respond across different timeframes, from seconds, to minutes. This is not the case for conventional power plants based on combined cycle gas turbine technology which can take several hours to reach operation at full capacity. Even if gas turbines can provide some level of flexibility by being run at partial load, this mode of operation is inefficient, driving up costs and carbon emissions.

On the other hand, flexible gas engine power plants are the perfect ally of renewable energies. Made up of multiple engines which can be fired-up instantaneously, these plants offer a large range in power supply availability which complements renewable energy without sacrificing efficiency. If a sudden rainstorm, for example, cuts the supply of solar energy and drives up electricity demand as lights are switched on, a number of internal combustion engines can be turned on within minutes to supply the required electric demand. They can be turned off just as quickly when the storm passes.

Expert studies conducted around the world show that flexible power plants based on internal combustion engine technology can unlock the full potential of renewable energy assets in the fleet, generating annual cost savings above 5%, reducing CO2 emissions, as well as reducing overall water consumption. Indeed, flexible power plants consume nearly 50% less water than similarly sized combined cycle gas turbine plants and 75% to 85% less water than a coal or nuclear plant with cooling towers. In a context of global warming and hydric stress, water consumption is a parameter that cannot be ignored.

For the country to successfully integrate the planned addition of ~3,5 GW of Hydro and ~5.2 GW of solar projects into the grid by 3030 and increase access to affordable and reliable electricity, a balanced power generation mix will be required. Gas is abundant, affordable, and offers a clear solution to meet the growing power demand in Nigeria. But most important is the need for long-term integrated energy planning. By deploying an integrated energy strategy with a focus on flexibility, Nigeria has what it takes to achieve a successful energy transition. Without it, Nigeria’s power sector will most likely remain inefficient and unreliable.

About the Author

Yusuff Wale is the Managing Director, Wartsila Marine & Power Services Nigeria Ltd. Wartsila is a global leader in smart technologies and complete lifecycle solutions for the marine and energy markets. He is a seasoned professional in Management, Sales, Marketing and Business Development in the Nigerian Oil and Gas and Power Industry. He started his career as a process engineer in one of the Nigerian Petroleum Oil Refineries. Over the years, he has been actively involved in large transactions of Turbo-Machineries into major FPSO projects in Nigeria as well as Internal combustion engines for both Industrial and Captive Independent Power Plants. He has presented technical papers at both local and international Oil, Gas and Power Conferences. He holds a MSc. and Bachelor of Engineering degrees in Chemical Engineering from the prestigious University of Lagos and Federal University of Technology, Minna, respectively and a miniMBA in Innovation, Growth & Digital Execution techniques for building category king companies, from the Tekedia Institute. He has attended many trainings both in Nigeria and abroad. He is a corporate member, Nigeria Society of Engineers (MNSE).

Yusuff Wale is the Managing Director, Wartsila Marine & Power Services Nigeria Ltd. Wartsila is a global leader in smart technologies and complete lifecycle solutions for the marine and energy markets. He is a seasoned professional in Management, Sales, Marketing and Business Development in the Nigerian Oil and Gas and Power Industry. He started his career as a process engineer in one of the Nigerian Petroleum Oil Refineries. Over the years, he has been actively involved in large transactions of Turbo-Machineries into major FPSO projects in Nigeria as well as Internal combustion engines for both Industrial and Captive Independent Power Plants. He has presented technical papers at both local and international Oil, Gas and Power Conferences. He holds a MSc. and Bachelor of Engineering degrees in Chemical Engineering from the prestigious University of Lagos and Federal University of Technology, Minna, respectively and a miniMBA in Innovation, Growth & Digital Execution techniques for building category king companies, from the Tekedia Institute. He has attended many trainings both in Nigeria and abroad. He is a corporate member, Nigeria Society of Engineers (MNSE).