Kenya’s Strathmore University, in collaboration with SYSPRO, a global provider of industry-built Enterprise Resource Planning (ERP) software for manufacturers and distributors have released research findings of a production and manufacturing industry in Kenya .

The study explored productivity and competitiveness of the manufacturing sector in Kenya, from close to 100 companies drawn from 12 sectors on the role of new technologies in improving the sector and the state of adoption and use of these new technologies.

The study, titled “An Investigation into the Implementation of Technological Aids and ERP Solutions in the Manufacturing Industry in Kenya”, had Prof. Ismail Ateya, Dean of Research and Innovation, as the principal investigator and Prof. Reuben Marwanga as the co-investigator.

The findings were presented at a launch event attended by Betty Maina, the Principal Secretary, State Department of Investment and Industry in the Ministry of Industry, Trade and Cooperatives, and Dr. Vincent Ogutu, Vice Chancellor Designate, Strathmore University.

It demonstrated that the most important initiatives that can increase competitiveness both for local and export markets (according to the manufacturers interviewed) are favorable taxes and favorable regional preferential treaties. Other factors included a reduction in the cost of production, upgrading the current technologies deployed and increasing production efficiency.

Speaking at the launch of the research findings, Prof. Ateya noted that over 85% of companies interviewed were either semi-automated or fully-automated with a majority still holding on to outdated production units because of the high cost of spare parts, unavailability of locally manufactured spare parts and inability to differentiate quality from fake until used. Counterfeits, he noted, were a large hindrance to local purchasing.

High software and hardware costs, as well as the lack of skilled labor, were cited as major hindrances to technology adoption. Manufacturers interviewed proposed to have tax incentives for technology purchases, better training for local technology partners, improved availability of new technologies locally, availability of affordable automation and robotics technology as well the availability of skilled technical workers.

Besides technology, the study revealed that more than half of the manufacturers interviewed felt that the government could still do more to make the sector competitive and attractive to potential investors.

Development of infrastructure, provision of exemptions, grants and subsidies as well as purchasing guarantee from the government were highly rated.

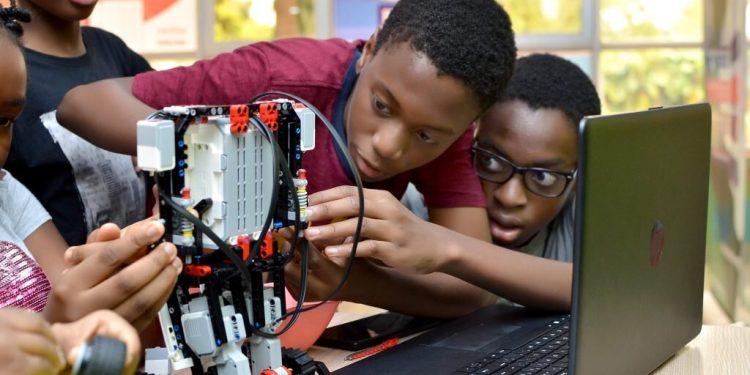

Support for apprenticeship, graduate internships and technical courses in universities was identified as a major initiative that would make local manufacturing an attractive business venture.

It was noted that over 50% of the respondents felt that Kenya’s manufacturing sector would have difficulty competing with counterparts in other developed countries that have advanced education and training systems.

Other notable factors that need to be urgently addressed include high cost of capital financing, which remains a major hurdle in the manufacturing sector, and energy which was reported as the main external factor that adversely affected business operations in the last 2-3 years.

Political climate, taxes, cheap imports, and exchange rates were rated as negatively impacting business operations while technical skills, labor wages, climate conditions, and visa requirements were rated as having the lowest adverse effect on the business operations comparatively.

Regarding future projections and strategic planning, companies interviewed prioritized product development, advertisement, and marketing, computer systems, hardware and software as potential investment areas to improve business operations in the next financial year.